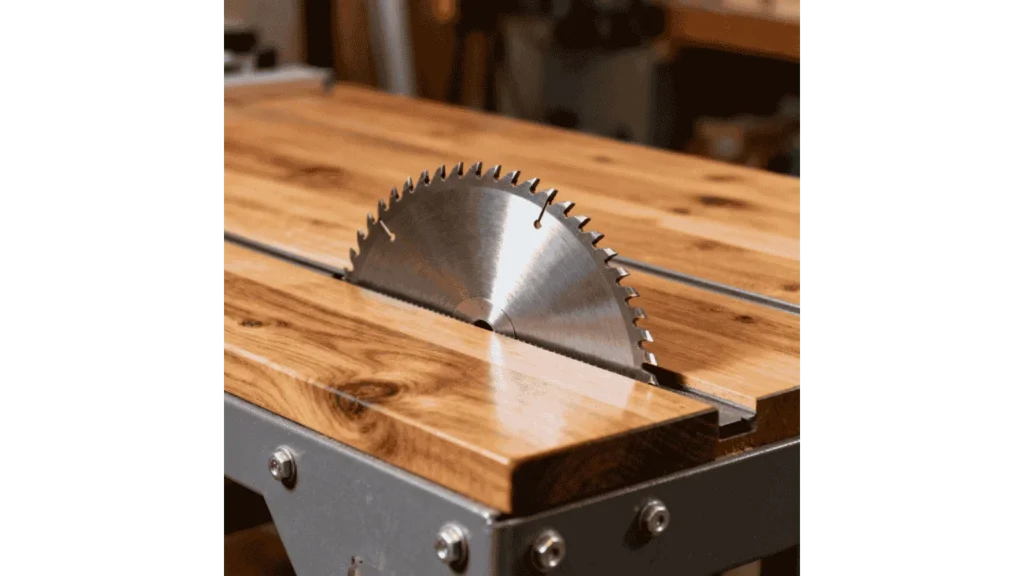

Table saws are essential tools in woodworking and construction, offering precision and versatility in cutting various materials. Whether you’re a professional carpenter or a DIY enthusiast, a table saw is often the cornerstone of a well-equipped workshop. From my experience, having a quality table saw can make a noticeable difference in both the quality of your cuts and the speed at which you complete your projects. The primary function of a table saw is to make straight, precise cuts, whether you’re working with wood, plywood, or other materials. This makes it an indispensable tool for creating clean, accurate cuts on almost any project.

Core Applications of a Table Saw

Ripping Lumber

One of the main functions of a table saw is ripping wood along the grain (lengthwise) to reduce its width. This is especially useful when you need to create uniform boards from larger pieces of wood. Table saws provide the most consistent, straight cuts when ripping lumber compared to hand saws, making them essential for building furniture or framing materials.

Crosscutting

Table saws are equally effective at crosscutting, or cutting wood across the grain (widthwise), to shorten pieces. This is particularly useful when trimming boards to the desired length, especially in larger woodworking projects. I’ve used my table saw for crosscutting countless times, as it ensures precise, square cuts that are critical for assembling various wooden pieces like bookshelves or cabinet frames.

You Might Also Like: How to Sharpen a Table Saw Blade?

Bevel and Miter Cuts

“A table saw with the ability to tilt the blade for bevel cuts is essential for tasks that require angled joints, like crown molding or picture frames,” says professional carpenter Tom Harris.

Table saws also excel at making bevel and miter cuts by tilting the blade to create angled cuts. Whether you need to create joints for frames, corners for furniture, or trim work, a table saw provides the precision necessary to achieve these angles consistently. Using a miter gauge along with the bevel adjustment on the saw results in clean, exact cuts for all my framing and trim projects.

Cutting Sheet Goods

Table saws are highly efficient for cutting large panels of plywood, MDF, or particleboard. These types of materials are commonly used in cabinetry and furniture projects. A table saw’s ability to slice through large sheets quickly and accurately is one of its significant advantages. I’ve relied on my table saw for cutting sheet goods down to size for cabinetry or shelving projects, as it minimizes the need for additional measuring or trimming.

Grooves, Dadoes, and Rabbets

Table saws can also be equipped with specialized blades or jigs to create grooves, dadoes, and rabbets, which are essential for joinery in cabinetry and shelving. These cuts allow for the precise fitting of parts together, such as when creating drawers or shelves. Having a table saw capable of making these cuts significantly improves the overall quality and efficiency of joinery in woodworking projects.

Types of Table Saws and Their Uses

“Choosing the right type of table saw for your needs can dramatically improve both your workflow and the quality of your work,” says tool expert Sarah Lopez.

Benchtop Table Saws

Benchtop table saws are compact and portable, making them ideal for small workshops or mobile use. They are great for light-duty tasks and DIY projects. These saws provide excellent precision for smaller cutting jobs like trimming wood or cutting small pieces for home improvement projects. They are especially useful for hobbyists who need a versatile, space-saving option without compromising on cutting performance.

Jobsite Table Saws

Jobsite table saws are designed for portability with enhanced durability to withstand the demands of construction sites. They are commonly used by contractors for on-site work, offering the right balance of power and mobility. These saws are equipped to handle the wear and tear of jobsite conditions while providing efficient cutting for large projects.

Contractor Table Saws

Contractor table saws are larger and more powerful, making them suitable for serious woodworking tasks. These saws offer greater cutting capacity and stability compared to benchtop models, allowing you to tackle a wider range of projects with greater precision. I’ve used contractor saws for framing and heavy-duty cutting, and their increased power and stability make them a top choice for professionals.

Cabinet Table Saws

Cabinet table saws are high-end models designed for professional use. They offer the highest level of precision and power, making them ideal for serious woodworkers who need reliable, accurate cuts. These saws are equipped with robust construction, large motors, and advanced safety features. From my experience, they are perfect for detailed woodwork or projects where absolute accuracy is non-negotiable.

Recommended Read: What is a Table Saw?

Safety Tips When Using a Table Saw

Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection when operating a table saw. Ensure that the workpiece is securely clamped before cutting to prevent movement. Keep your hands and other body parts clear of the cutting path at all times. Regularly inspect your saw for wear or damage, such as loose parts or dull blades, to ensure safe operation and maintain cutting precision.

“Taking the time to follow proper safety procedures ensures you’ll avoid injuries and get clean, precise cuts every time,” advises safety expert David Miller.

Further Reading: How to Use a Table Saw?

FAQs

What is a table saw used for?

A table saw is primarily used for making straight, precise cuts in materials like wood, plywood, and MDF.

How does a table saw differ from a circular saw?

While both are used for cutting, a table saw provides a stable surface and guide, allowing for more accurate and repeatable cuts, especially for larger materials.

Can a table saw cut metal?

Some table saws can cut metal with the appropriate blade, but it’s essential to check the manufacturer’s specifications and use the correct blade type.

What safety precautions should be taken when using a table saw?

Always wear safety goggles, gloves, and hearing protection. Ensure the material is securely clamped and keep hands clear of the cutting path.

How do I maintain my table saw?

Regularly clean the saw, check for blade wear, and ensure all parts are functioning correctly. Refer to the manufacturer’s manual for specific maintenance guidelines.

Discover the versatile applications of a table saw. Learn what a table saw is used for, including cutting wood, plywood, and more, with tips for safe operation.

Final Takeaways

A table saw is an indispensable tool for making precise, straight cuts in a variety of materials. Choosing the right type of table saw, whether benchtop, jobsite, contractor, or cabinet, depends on the complexity of the cuts you need to make and the space available in your workshop. Proper safety precautions and regular maintenance are crucial for ensuring longevity and safe operation. Whether you’re a DIY enthusiast or a professional, a table saw can make your cutting tasks faster, more accurate, and more efficient.

- 7 Best Professional Jigsaws Tested for 2026 - January 20, 2026

- 7 Best Jigsaws for Home Use in 2026 - January 20, 2026

- 7 Best Jigsaws for Beginners Tested in 2026 - January 20, 2026