Ever wondered what gives woodworkers those clean, perfect cuts every time? The secret lies in the table saw, a powerhouse tool that defines precision and control. Whether you’re building furniture, remodeling your home, or working on DIY projects, understanding what a table saw is and how it works can completely change the way you craft.

What Exactly Is a Table Saw and How Does It Work?

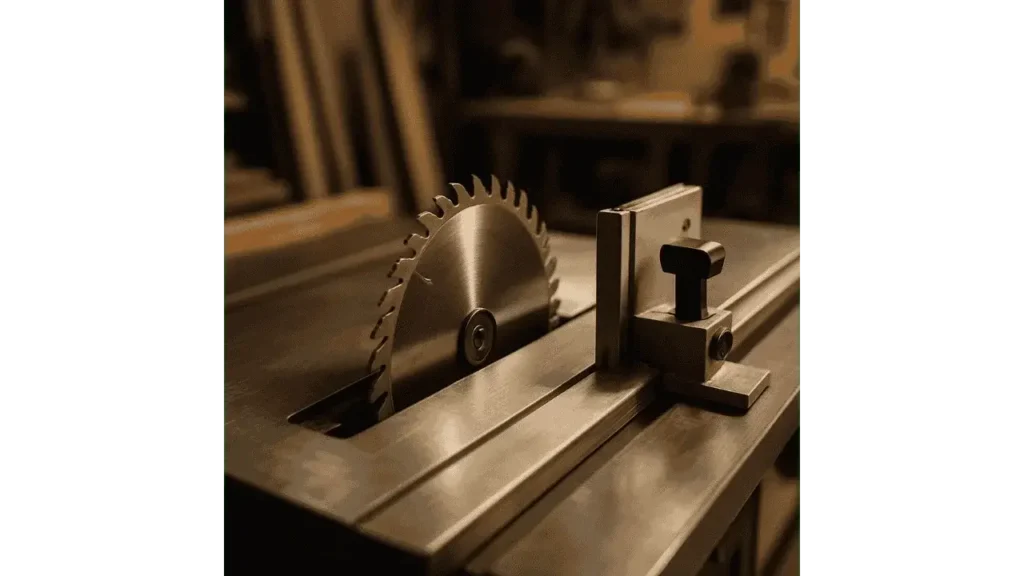

A table saw is a stationary power tool built for precise, straight cuts in wood, plywood, and similar materials. It uses a circular blade mounted on an arbor, powered by an electric motor. The wood moves across the fixed blade, delivering smooth, accurate cuts every time. This setup ensures stability and precision you can’t get from handheld saws. From my experience, once you learn to adjust blade height and angle, it quickly becomes the most efficient tool in your workshop.

In simple terms, if you’ve ever wondered what a table saw is used for, it’s the go-to tool for accurate, repeatable cuts that define professional woodworking.

Mark Jensen, Professional Woodworker and Instructor explains,

“A table saw is the heart of any workshop. Once you understand its rhythm, how the wood moves, how the blade reacts, you’ll realize it’s more about control than power.”

What Are the Different Types of Table Saws?

Different projects require different types of table saws, each designed with unique strengths. Knowing which type suits your needs helps you work more efficiently and safely.

Benchtop Table Saws:

These are compact and portable, perfect for beginners or homeowners with limited workspace. They’re affordable and handle basic cutting jobs with ease.

Jobsite Table Saws:

Built for mobility and power, jobsite saws feature sturdy stands and wheels for easy transport. They offer stronger motors and improved accuracy for on-the-go projects.

Contractor Table Saws:

Heavier and more stable than portable models, contractor saws deliver cleaner, more powerful cuts. They’re ideal for mid-level projects and small professional workshops.

Cabinet Table Saws:

The most powerful option, cabinet saws are enclosed for better dust control and reduced vibration. They’re built for precision and long-term use in professional shops.

Hybrid Table Saws

Combining cabinet-saw accuracy with contractor-saw convenience, hybrid models are a balanced choice for serious hobbyists. They offer great value and dependable performance.

Sarah Coleman, Woodshop Owner and Tool Reviewer

“Your workshop setup determines the saw you need. A benchtop saw may fit a garage, but a cabinet saw belongs to a craftsman chasing precision day after day.”

Choosing the right table saw depends on your space, skill level, and project scale. For small workshops, a benchtop or hybrid model works best, while professionals rely on cabinet saws for unmatched precision.

Recommended Reading: How to Use a Table Saw?

What Can You Do with a Table Saw?

A table saw can perform several types of cuts that are essential in woodworking. You can rip boards to width, crosscut lumber to length, and bevel edges for joints or decorative trim. With additional jigs, you can even cut dados, grooves, and rabbets for cabinetry.

From personal experience, the table saw often becomes the centerpiece of any workshop, it’s the tool you’ll use most often once you understand its potential.

Once you understand what a table saw is capable of, you’ll see why it’s considered the centerpiece of every serious workshop.

What Safety Measures Should You Always Follow?

Safety is what separates a confident craftsman from a careless one. Always unplug the saw before changing blades, use a push stick when cutting narrow pieces, and keep the riving knife aligned to avoid kickback. Wear safety glasses and hearing protection every time.

Make sure the fence and miter gauge are properly aligned, and never reach over a spinning blade. A well-maintained table saw is safer and produces cleaner cuts, two things that always go hand in hand.

David Torres, Safety Trainer and Carpentry Expert

“Respect the blade every time you switch it on. Most accidents happen when you rush or assume you’re experienced enough to skip precautions.”

What Mistakes Should You Avoid When Using a Table Saw?

One of the most common mistakes is rushing the cut. Pushing material too fast causes burning or binding, and cutting without a fence leads to uneven results. Another mistake is failing to check blade sharpness and alignment before starting a project.

Beginners also overlook dust collection, which affects visibility and air quality. Keeping the blade clean and using proper accessories reduces both risk and rework.

FAQs About Table Saws:

Q1. What’s the difference between a table saw and a circular saw?

A table saw is stationary and offers higher precision, while a circular saw is portable and better for rough cuts or on-site trimming.

Q2. Can a table saw cut metal or plastic?

Most table saws are designed for wood. However, with the correct blade, you can cut certain plastics or soft metals like aluminum, always check the blade rating first.

Q3. What size blade do most table saws use?

The standard size is 10 inches, which balances depth of cut and motor performance for most projects.

Q4. How powerful should a table saw be for home use?

A 1.5 to 2 horsepower motor is sufficient for general woodworking at home. Larger projects may require more power.

Q5. Is a table saw safe for beginners?

Yes, with proper setup, safety gear, and attention to technique. Start with slow, deliberate cuts and work up to more complex tasks.

Key Takeaways:

A table saw is one of the most useful tools a homeowner or woodworker can invest in. Understanding what a table saw is and how it works gives you control, precision, and speed in every cut. With proper setup and care, it becomes the backbone of any woodworking project.

- 7 Best Professional Jigsaws Tested for 2026 - January 20, 2026

- 7 Best Jigsaws for Home Use in 2026 - January 20, 2026

- 7 Best Jigsaws for Beginners Tested in 2026 - January 20, 2026