Keeping a track saw blade sharp is key to clean, effortless cuts and longer tool life. A dull blade doesn’t just slow your work, it burns wood, tears edges, and forces the motor to work harder. I learned this firsthand when my cuts started smoking even though my setup hadn’t changed. After sharpening the blade, the saw felt brand new again.

Sharpening your blade at the right time can save money and improve accuracy, but knowing when to sharpen versus replace is just as important. In this guide, you’ll learn how to identify dullness, understand blade types, prepare for sharpening, and safely restore your blade using professional or DIY methods.

When to Sharpen?

Blades lose sharpness gradually, often without obvious signs until the cut quality declines. Burning on wood edges, rough cuts, and slower feed rates are clear warnings. If you hear a strained motor sound or feel vibration during cutting, your blade’s edge is likely dull.

Most track saw users find that sharpening after 20 to 30 hours of active use keeps performance steady. For professionals cutting daily, that might mean sharpening every few weeks. However, once teeth chip, crack, or wear down too far, replacement is the only safe choice. Always inspect carefully before deciding whether sharpening is worthwhile.

You Might Also Like: How to Use a Track Saw Blade?

Blade Types & Sharpenability

Track saw blades generally fall into two categories: carbide-tipped and high-speed steel (HSS). Carbide-tipped blades hold an edge longer and are the standard for most modern saws. They’re harder to sharpen by hand but ideal for professional regrinding. HSS blades are softer and cheaper, making them suitable for light-duty use or manual sharpening.

It’s worth sharpening carbide blades only if they’re good quality and not excessively worn. Budget blades with thin carbide or uneven teeth often cost more to sharpen than to replace. Each resharpening slightly reduces tooth height, so after several sessions, replacement becomes the practical option.

Prep before Sharpening

Before sharpening, clean the blade thoroughly to remove pitch, resin, and dust buildup. Use a mild degreaser or blade cleaner to dissolve residue without scratching the metal. A clean blade helps you see damage and ensures accurate sharpening.

Inspect for cracks, missing teeth, or warping, these are signs the blade shouldn’t be reused. Mark the first tooth you’ll sharpen to maintain orientation, and secure the blade firmly in a jig or vice. Stable positioning prevents uneven sharpening and maintains tooth geometry.

Methods for Sharpening

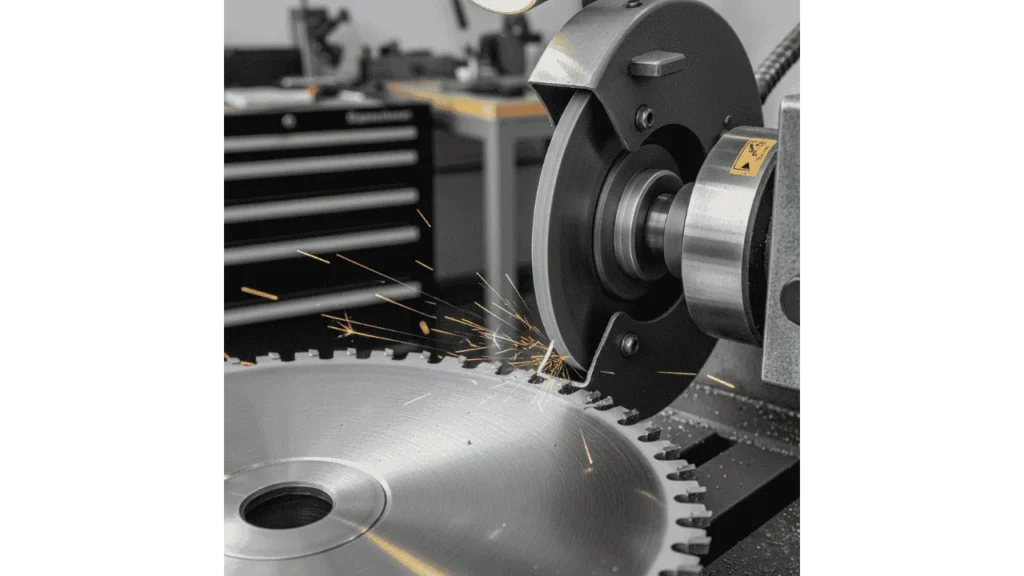

Professional Service

Most professionals use diamond grinding machines for carbide-tipped blades. These machines restore precise angles, balance, and symmetry that are difficult to match at home. Many sharpening services charge between $10 and $20 per blade depending on diameter and tooth count, making it a worthwhile option for high-quality blades. The process includes cleaning, grinding, and balancing, extending a blade’s life several times over.

DIY with Diamond Wheel/Jig

If you prefer doing it yourself, use a diamond grinding wheel and a stable sharpening jig. Set the blade at the original tooth angle, usually marked by the manufacturer. Work tooth by tooth, taking light passes to maintain uniform sharpness. Consistency in angle and depth is critical; even a small deviation can cause uneven cutting or noise.

Hand Tools (Steel Blades Only)

For steel blades, not carbide, you can use files or fine whetstones to sharpen manually. Hold the file at the existing bevel angle, draw lightly across each tooth, and keep strokes consistent. This method works best for occasional maintenance or small blades but requires patience and control.

“Hand sharpening is about feel. Light, even strokes matter more than speed,” explains Jim Tolpin, author of Table Saw Magic and veteran woodworking instructor.

Step-by-Step Procedure

Start by removing the blade from your track saw and cleaning it thoroughly. Once it’s secure in your jig, identify the original tooth angle and set your grinder or file accordingly. Begin sharpening one tooth at a time, maintaining even pressure and identical strokes. Move methodically around the blade until all teeth are sharpened.

After sharpening, remove any burrs or residue using a soft brass brush or cloth. Balance the blade if needed to prevent vibration during use, then reinstall it carefully. Always make a test cut on scrap wood to check for smoothness, alignment, and sound.

“A sharp blade should glide through material without changing pitch or pressure, any strain means your angles are off,” says Chris Marshall, senior editor at Woodworker’s Journal.

Best Practices

Avoid overheating the blade by using light passes, excess heat can damage carbide or warp steel. Keep a log of sharpening dates to track performance and wear patterns. Don’t grind too deeply; preserving tooth geometry is vital for both cut quality and blade longevity. After each session, check balance to ensure vibration-free operation.

Related: What is a Track Saw Used for?

Safety Considerations

Always wear eye protection, hearing protection, and a dust mask during sharpening. Flying sparks and metal dust can be harmful. Make sure the blade and sharpening tool are firmly secured and free from vibration before starting. Avoid wearing loose sleeves or jewelry that could catch on rotating parts. Unplug all tools before adjusting or removing blades.

“Sharpening safety starts before the grinder runs, secure your work first, then think about the edge,” advises Tom Silva, general contractor from This Old House.

FAQs

1. How often should I sharpen a track saw blade?

A track saw blade should be sharpened every 40 to 50 hours of cutting or whenever you notice burning or rough edges. Keeping it sharp ensures smoother, cleaner cuts and less strain on your saw.

2. What tools do I need to sharpen a track saw blade at home?

To sharpen a track saw blade yourself, you’ll need a diamond grinding wheel, a sharpening jig, and safety gear. These tools help maintain tooth angle and prevent uneven wear.

3. Can I sharpen a track saw blade without removing it from the saw?

It’s not recommended. Always remove the blade from your track saw before sharpening. This gives you better control, prevents accidents, and ensures each tooth is sharpened evenly.

4. How can I tell if my track saw blade is too dull to sharpen?

If the blade has chipped or missing teeth, visible warping, or burns wood even after cleaning, it’s beyond sharpening. In that case, replacing it is the safest option.

5. Should I sharpen a carbide track saw blade differently?

Yes. Carbide track saw blades need to be sharpened using a diamond wheel or by a professional service. Standard metal files won’t work on carbide and can damage the blade.

6. How do I balance a track saw blade after sharpening?

After sharpening, place the blade on a balancing arbor. If it tilts or drifts to one side, lightly grind the heavier section until it stays level. A balanced blade reduces vibration and ensures smooth operation.

7. Is it better to sharpen a track saw blade by hand or professionally?

For most users, professional sharpening is more accurate and longer-lasting. However, if you have experience and the proper equipment, you can successfully sharpen a track saw blade at home.

Final Takeaways

Sharpening a track saw blade restores performance and extends its lifespan, but not all blades are worth saving. Clean and inspect before every sharpening, and choose professional diamond grinding for carbide-tipped blades whenever possible. Whether you DIY or use a service, finish by balancing and test-cutting to confirm smooth operation. A sharp, well-maintained blade keeps your track saw cutting safely, efficiently, and precisely every time.

- 7 Best Professional Jigsaws Tested for 2026 - January 20, 2026

- 7 Best Jigsaws for Home Use in 2026 - January 20, 2026

- 7 Best Jigsaws for Beginners Tested in 2026 - January 20, 2026