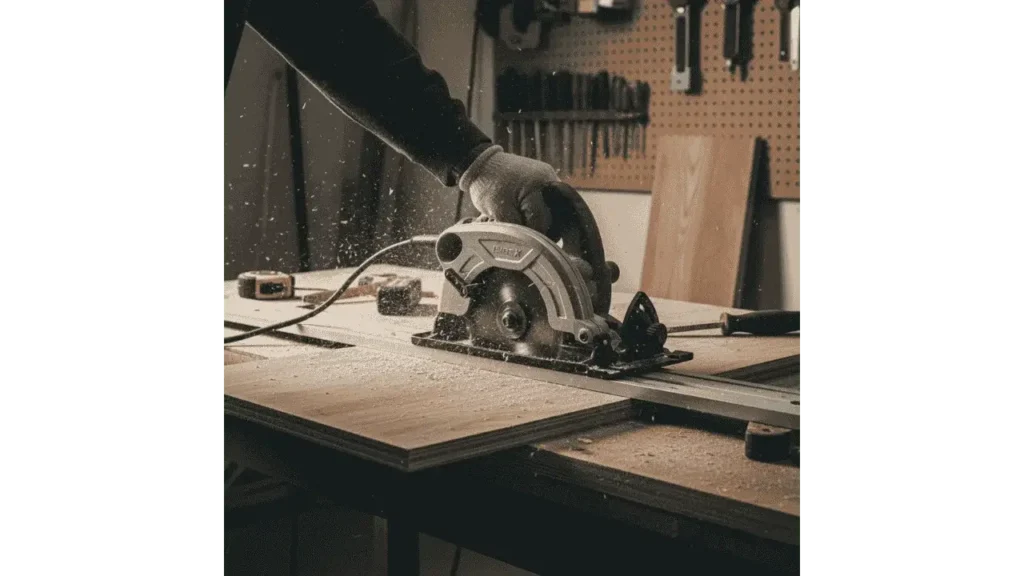

Cutting plywood with a circular saw can be smooth and precise when you know how to prevent splintering and tear-out, which are the most common issues people face with large sheet goods. A circular saw is an excellent tool for ripping or crosscutting plywood because it’s portable, powerful, and easier to manage on a large plywood sheet than a table saw, especially when working alone. The key steps always come down to choosing the right circular saw blade, supporting the sheet properly, marking accurate lines, and following a controlled cutting technique. Over years of working with cabinet-grade plywood and construction panels, I’ve learned that accuracy depends as much on setup as it does on the cut itself, and safety should never be secondary when handling large sheet materials.

What Tools and Setup Do You Need Before Cutting Plywood with a Circular Saw?

A proper setup begins with a well-maintained circular saw, a fine-toothed blade or high-tooth-count blade, and a reliable cutting guide or straight-edge guide to keep the cut line true. You’ll also need clamps to clamp down the sheet firmly so it doesn’t shift. For the work surface, placing the plywood on sawhorses, 2×4 supports, or a sheet of rigid foam board is ideal because it stabilizes the material and prevents binding during the cut. Foam is especially useful because you can lay the entire sheet flat and cut directly into it without risking damage to the blade or worktable. Safety gear is essential; safety glasses, a dust mask, ear protection, and gloves keep you protected from debris and vibration while you use a circular saw on larger materials.

Which Circular Saw Blade Works Best for Cutting Plywood Cleanly?

A smooth, splinter-free cut begins with the right blade. Plywood requires a carbide-tipped blade with a high tooth count, usually forty to sixty teeth, to slice cleanly through the layered structure of the sheet. Standard framing blades tend to tear the veneer because their aggressive teeth are made for fast cuts rather than clean ones. Specialized plywood blades or high-tooth-count blades maintain a smoother cut and reduce the chance of tear-out along the edge. It’s also crucial to check the sharpness of your blade, since even the right type will splinter plywood if it’s dull.

As carpentry instructor Ryan Kepler puts it,

“If you want clean plywood cuts, the blade matters more than the saw, upgrade the blade, and the plywood will tell the difference immediately.”

How Should You Prepare and Mark the Plywood Before Cutting?

Start by marking your cut line precisely. Use a straight-edge ruler or chalk line to create a clear guide, then consider scoring the line lightly with a utility knife to reduce splintering across the top veneer. Identify the finished side of the sheet and place it facing down, because most circular saws cut upward and will leave the cleanest edge on the underside. If the plywood is prone to chipping, applying a strip of painter’s tape directly over the cut line helps reinforce the top layer. When you’re working with a large plywood sheet, always orient the sheet properly and give yourself room to move, so you can follow the cut fluidly without stopping or readjusting.

How Do You Set Up a Guide or Straightedge for a Perfect Cut?

A cutting guide is one of the most reliable ways to keep your circular saw on track. You can use a dedicated guide rail, a clamp-on straightedge, or even the factory edge of another plywood sheet as a long, straight reference. Make sure your clamps are positioned where they won’t interfere with the saw’s travel path. Measure the distance from the saw’s shoe to the blade and offset your guide accordingly so that the saw’s base runs perfectly parallel with the cut line. When you align the saw with the guide, the blade follows your mark cleanly and accurately, allowing a long plywood rip to stay straight without wandering.

What’s the Correct Technique for Cutting Plywood with a Circular Saw?

A smooth cut starts with letting the saw reach full speed before touching the wood. Once the blade is moving, keep steady forward pressure, but never force it; letting the blade do the work is the key to preventing splintering. Maintain both hands on the saw and press the shoe firmly against the guide as you move forward. Supporting the sheet along its length prevents sagging or pinching, especially on the off-cut side. Allow the scrap piece to fall freely rather than holding it, because holding the off-cut can lead to binding. Always keep the blade guard unobstructed and ensure it returns smoothly as the cut finishes.

As woodworking specialist Laura Jensen often tells students,

“A circular saw rewards patience, slow, steady movement will always give you a better finish than rushing the cut.”

How Can You Prevent Splintering or Tear-Out When Cutting Plywood?

Splinter control begins with using a fine-toothed blade and keeping the finished side down so that the cleaner edge ends up where it matters most. Scoring the top surface before cutting helps reduce splintering on veneered sheets, and painter’s tape reinforces the fibers along the cut line. Cutting slowly reduces heat and vibration, which are two major causes of tear-out. Supporting the sheet fully, such as placing the entire plywood piece on a sacrificial foam board, prevents movement that can break the veneer. With a good blade and stable support, you can cut plywood while maintaining a crisp, splinter-free edge across both long rips and shorter crosscuts.

What Safety Tips Should You Follow When Cutting Plywood with a Circular Saw?

Always disconnect the saw from power before adjusting or changing the blade. Keep your hands far from the blade path at all times, and never reach under the sheet while cutting. Support the sheet fully to prevent pinching or sudden collapse around the blade, which can cause kickback. Maintain a firm stance and grip, and allow the blade to come to a full stop before setting the saw down. A stable setup protects both your cut quality and your personal safety, especially when handling larger sheets that can shift unexpectedly.

Frequently Asked Questions (FAQs):

Q1: What is the best blade for cutting plywood with a circular saw?

The best choice for cutting plywood with a circular saw is a fine-tooth carbide blade with at least 40–60 teeth. This type of blade minimizes splintering and gives you a cleaner edge, which is especially important when working with cabinet-grade or finished plywood.

Q2: How do I keep plywood from splintering when using a circular saw?

To reduce splintering while cutting plywood with a circular saw, face the good side down, score the cut line, and use a high-tooth blade. Applying painter’s tape or using a sacrificial board beneath the plywood also helps keep the fibers supported for a smoother edge.

Q3: Do I need a guide to cut plywood with a circular saw?

While you can cut freehand, using a guide when cutting plywood with a circular saw produces straighter results and prevents wandering. A clamped straightedge or guide rail keeps the saw aligned, especially on long cuts where accuracy matters most.

Q4: Should plywood be cut with the good side up or down?

When cutting plywood with a circular saw, place the good side facing down because the blade’s teeth cut upward. This reduces tear-out on the side that will be most visible in your finished project. The underside of the cut is typically much cleaner using this method.

Q5: Can I cut large plywood sheets alone with a circular saw?

Cutting plywood with a circular saw alone is possible if the sheet is properly supported on sawhorses or foam insulation boards. The key is preventing movement and keeping the entire sheet level so the cut remains smooth, safe, and controlled.

Final Takeaways

Cutting plywood with a circular saw becomes significantly easier and more accurate when you choose the right blade, support the sheet properly, and follow a deliberate cutting technique. Clean cuts begin with a fine-tooth or high-tooth-count blade, accurate marking, and a solid guide to keep the saw moving in a straight line. Preventing splintering involves orienting the sheet with the finished side down, scoring the cut line, and supporting the material fully along its length. Safety remains essential, from clamping the sheet securely to letting the saw reach full speed before cutting. With the right preparation and attention to detail, even large sheet-goods ripping becomes clean, controlled, and dependable.

- 7 Best Professional Jigsaws Tested for 2026 - January 20, 2026

- 7 Best Jigsaws for Home Use in 2026 - January 20, 2026

- 7 Best Jigsaws for Beginners Tested in 2026 - January 20, 2026